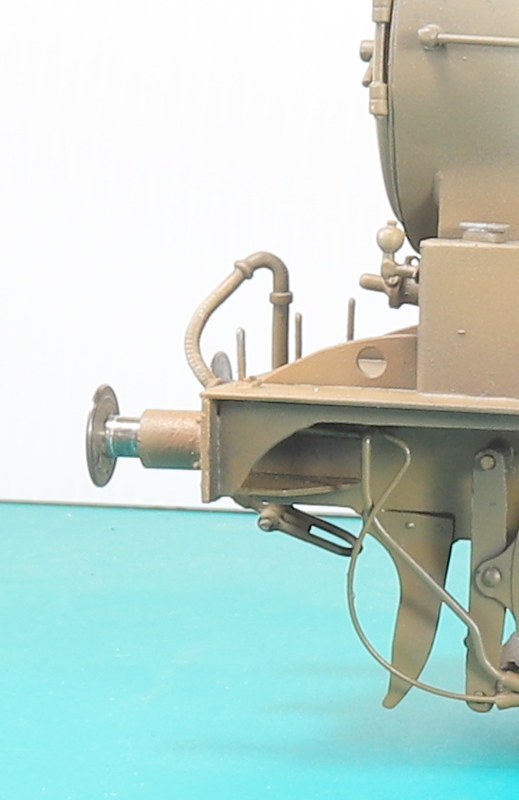

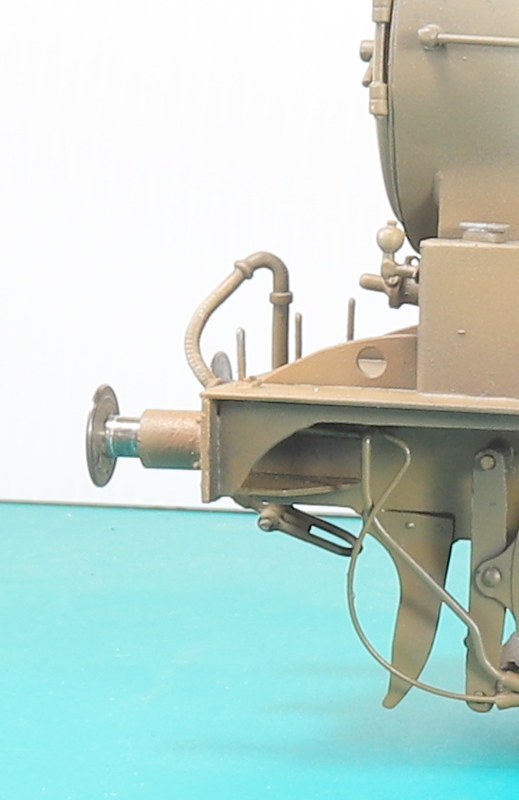

Recently while attempting to finish off all the little details of the J6 I had a bit of a conundrum. While I had fitted the front buffers previously to check that they went through the holes okay (I have had them in the past that haven’t and the hole had needed easing) I hadn’t actually tried to fit them with the body on.

What I found was that the 8BA nuts fouled the strengthening plates on the chassis and that the threads on the actual buffer heads hadn’t quite been threaded deep enough to pull the thicker part of the ram into the buffer stock. I recalled that David Hill of Gladiator had built one of these kits so I emailed David to ask how he had overcome the problem of the nuts fouling the chassis and I also mentioned about the threads not being deep enough. At this point although I could turn some replacements, the easier route would be to just run a die down them to make the thread a little deeper. What I was struggling with was working out the eternal problem of how to hold it securely to thread it.

As I have always found when emailing David, he responded very promptly and advised that he had filed flats on the nuts to clear the strengthening plates and he apologised about the threads and offered to replace the buffer heads. Now by this time I had my thinking head on and had worked out how to hold the existing buffer heads to add a few more threads.

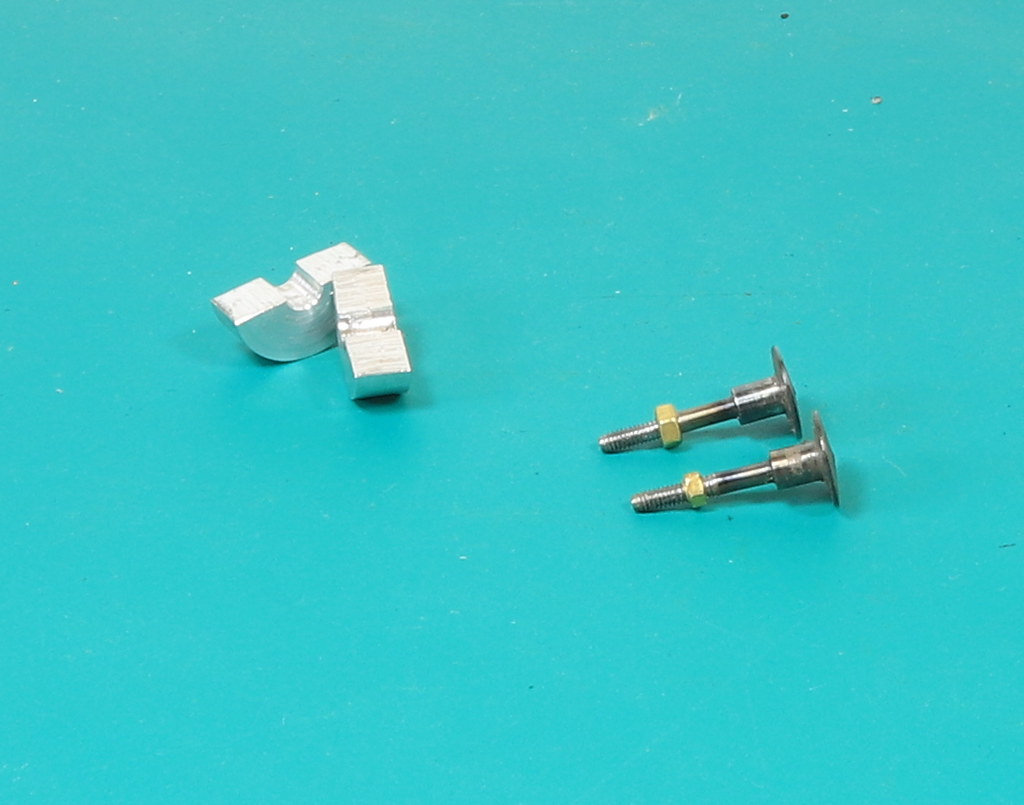

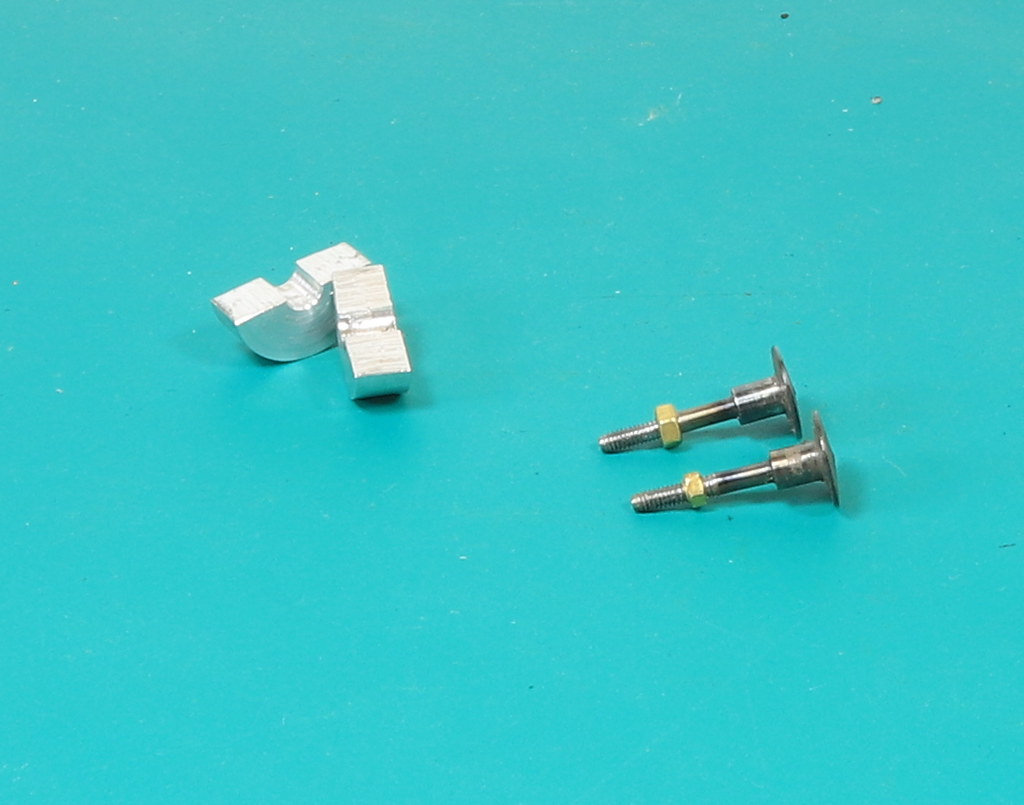

Last night I decided to have a go. I had short stub of 16mm aluminium bar which I drilled 4mm x 5mm deep. Then I parted off a 5mm length and made a slit down one side to allow the centre hole to be squeezed to grip the buffer head.

Sadly, the buffer ram behind the head was 3.8mm and having drilled it 4mm (the nearest sized bit that I had) I found that the aluminium wasn’t quite flexible enough to tighten and grip the ram. I quickly sawed the rest of the way through making two halves these then gripped the ram and a few more threads were quickly added to both of them.

Next was what to do about the 8BA nuts fouling the chassis. I decide to see if I could drill out a 10BA nut and tap it 8BA. The 1.8mm drill bit was either two big or two small to be gripped tightly in the myriad of pin vices that I have so in the end I gripped the drill bit in a spare Jacobs chuck and used that to ease out the hole in the nut. I used my 10BA nut spinner to hold the nut while drilling and tapping to save faffing about trying to hold it squarely in a vice.

The next small issue was that the tail of the buffer was visible beyond the valence. To overcome this, I took 5mm of each of them and they became a snug fit behind the buffer plank (while still retaining some movement against the spring) and invisible once the body is on the chassis.