Atlantic 3279 wrote: ↑Mon May 17, 2021 8:40 pm

I'm continuing to like it!

As an alternative to the now scrapped idea of printing the steps as part of the tank and bunker unit, it occurs to me that IF the shapes and sizes of the frame cut-outs, plus the axlebox spring units are sufficiently correct, then it wouldn't be a massive job to add steps manually to the frames, from metal strip or even from plastic, reshaping the frame ends first if necessary, and perhaps slotting those ends so that the treads for the steps can sit secure in the slots, rather than just being glued on their inner edges.

If the frame shapes and surface details are a poor match to the NE type, how hard a job would it be to print the frames too?

Hi Graeme,

Thank you!

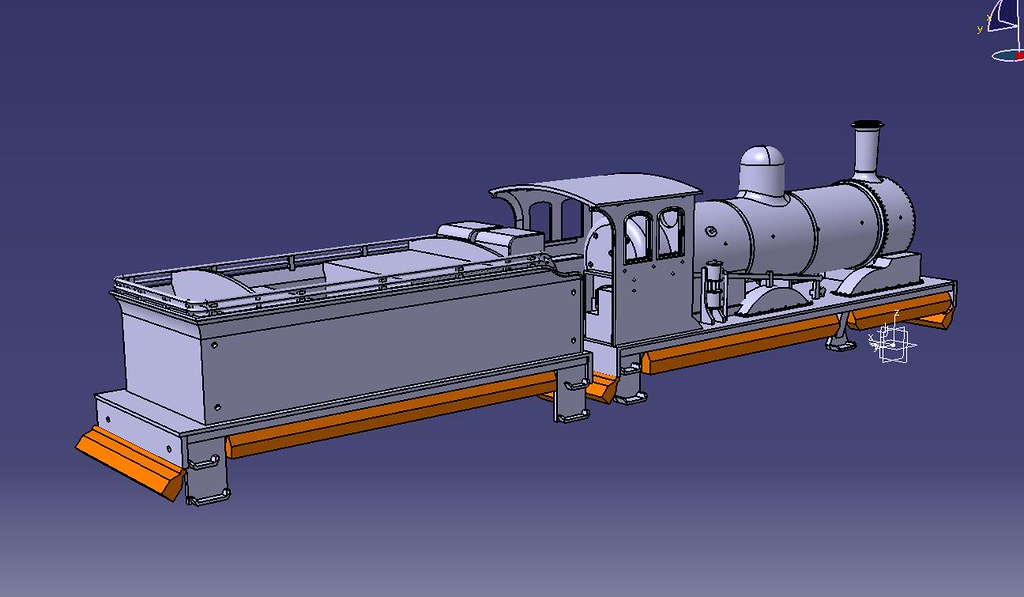

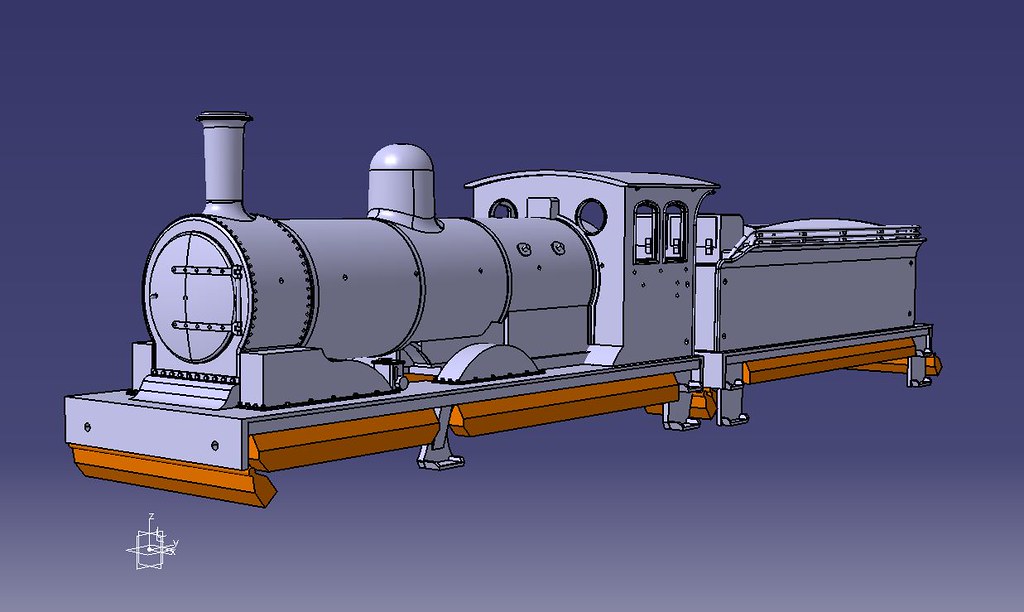

Okay so frames, dimensionally, they're a good match to the originals, in length, and the D shape cut outs are close, to some variants, the NE tenders used did change from time to time, the D sometimes having less of a homogenous curve, and more of a square with two radiuses. So its not ideal for the latter, unless someone wishes to file the shapes out.

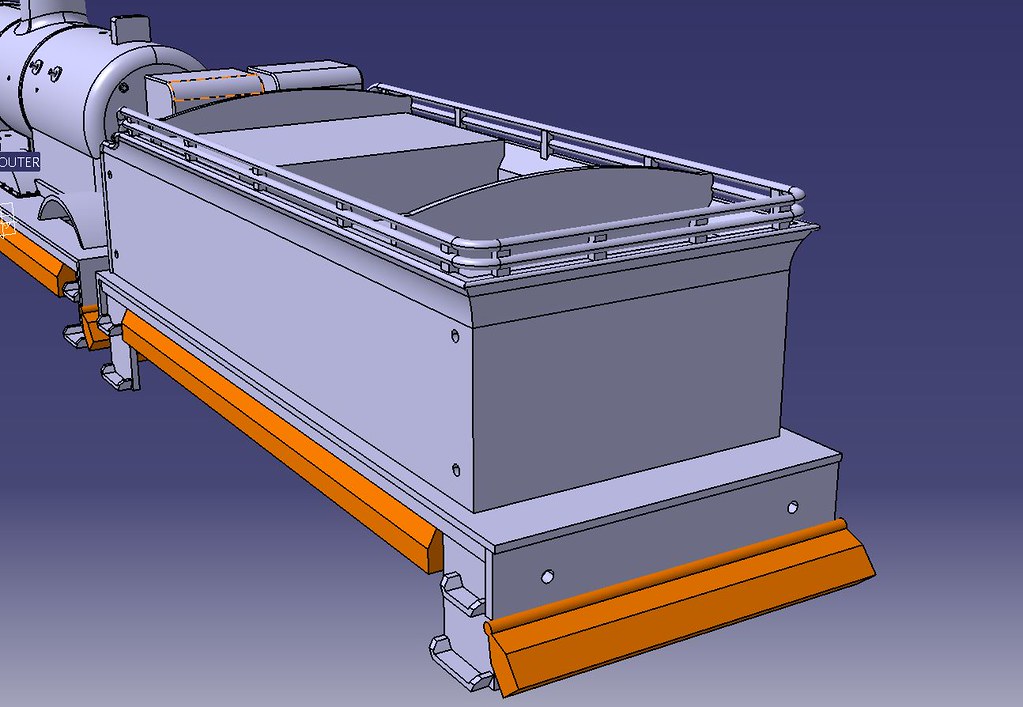

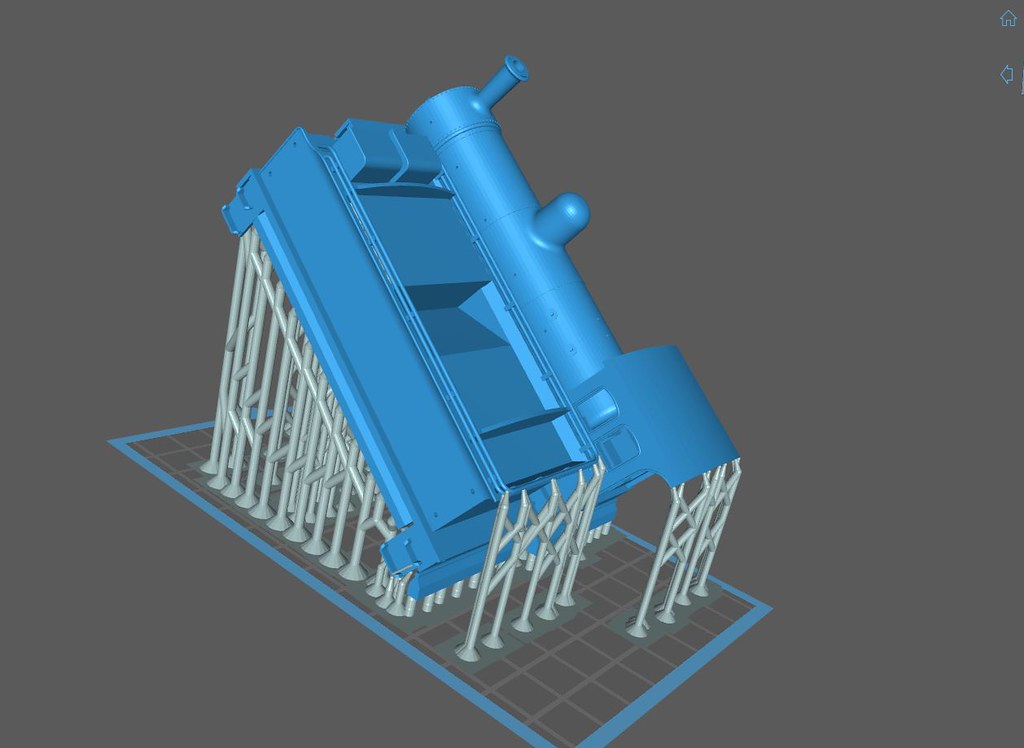

I agree re the steps, There is enough land at each of the bufferbeams to create notches to slot steps into, and I'll keep that in mind. Once the latest print comes off, I'm looking for stability of the beams, and then i'll see if slots/notches can be introduced, even if for people just to use brass strip, which would give a more dimensionally correct step (bearing in mind 1" is 0.33mm, and steps are typically 1/2 plate or less, so printing features that thin and long is a real challenge, on any print technology at present).

Printing frames is perfectly practical, Mike Trice on RMweb does it for coach bogies, however, from my own experience, I've been happier to use RTR components, as long slender frame parts are a notch harder to tune on a printer than complex boxing type parts which are naturally stronger by virtue of their shape. Moreover I just really like to avoid making printed parts that interact with mechanical components! I did do so for the S1 and LH&JC No.29, in respect of their rear truck/bogies, but I'd prefer to avoid it if I can.

For some, the frames would be a must if I'm honest, however, my view is, I'm using an RTR arrangement for the loco, accepting a compromise in terms of behind-wheel frame detail and shape, in order to gain a very simple conversion to achieve a J21, and if I do that on the loco, I'm happy to do that on the tender, on the proviso that whatever is used, provides an externally accurate tender body. Had I used a J15 donor, knowing its tender is significantly shorter than required, I'd have definitely been doing a full tender, or looking for a suitable donor elsewhere, as it is, the C-class provides a good all round donor.

Thanks, Paul.