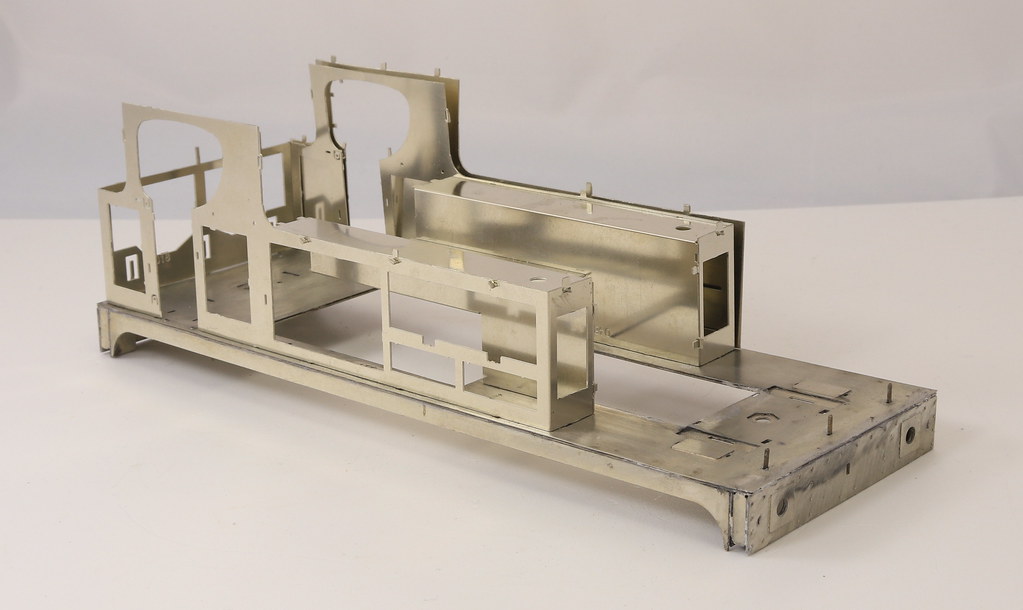

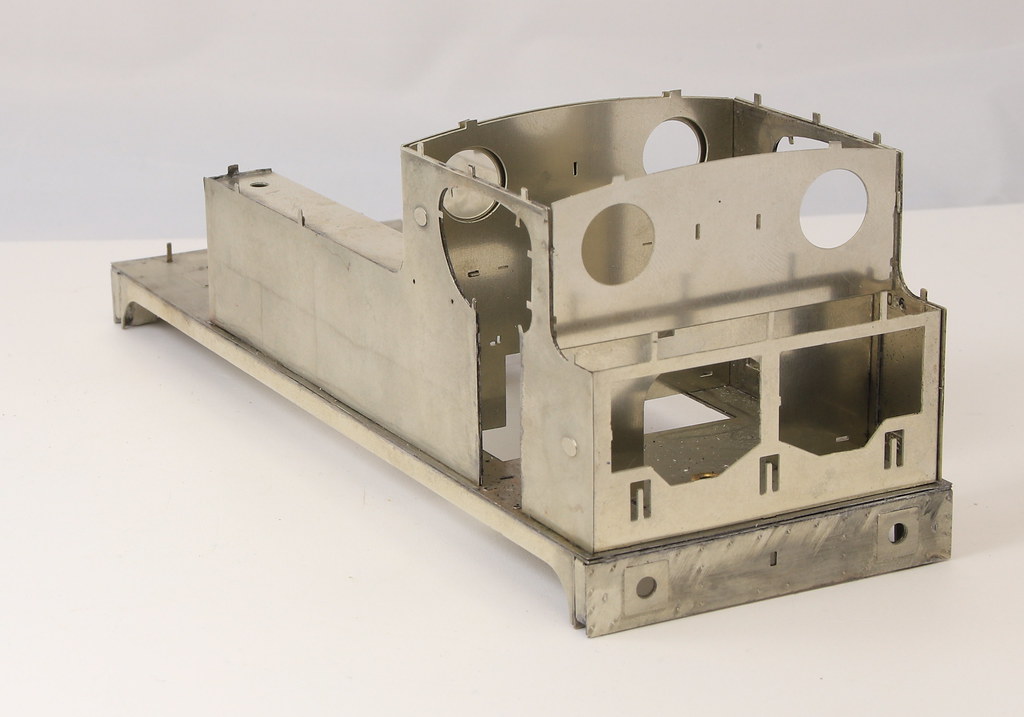

Having made the decision a couple of weeks or so ago, I made a start that weekend on a GP Models Robinson GCR Class 5A. I previously built one of these for myself but finished mine as an LNER J63. This one is to be finished as a GCR example.

Upon opening the box I found that the gent that I am building it for had already supplied a few extras but after examination of the castings bag, it revealed that some of them were quite poor. I Although I replaced a few of the more vulnerable castings like Oilers etc. I don’t recall the castings in my kit as being too bad so I was a little surprised. An exchange of emails later had me placing an order with Laurie Griffin for a few items. The one casting that was in my view poor but not available anywhere as a replacement (that I know of) was the backhead. This is a resin casting and perhaps the moulds were worn from when I got my kit, as mine was perfectly usable.

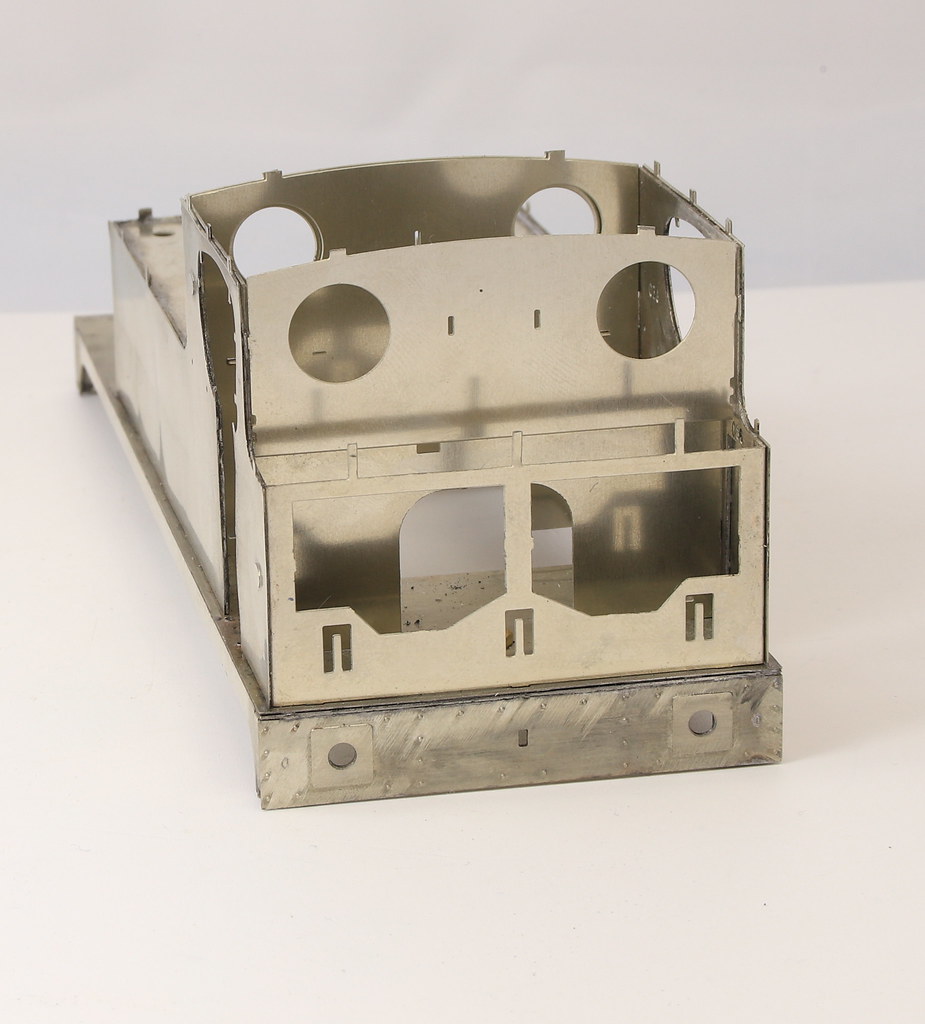

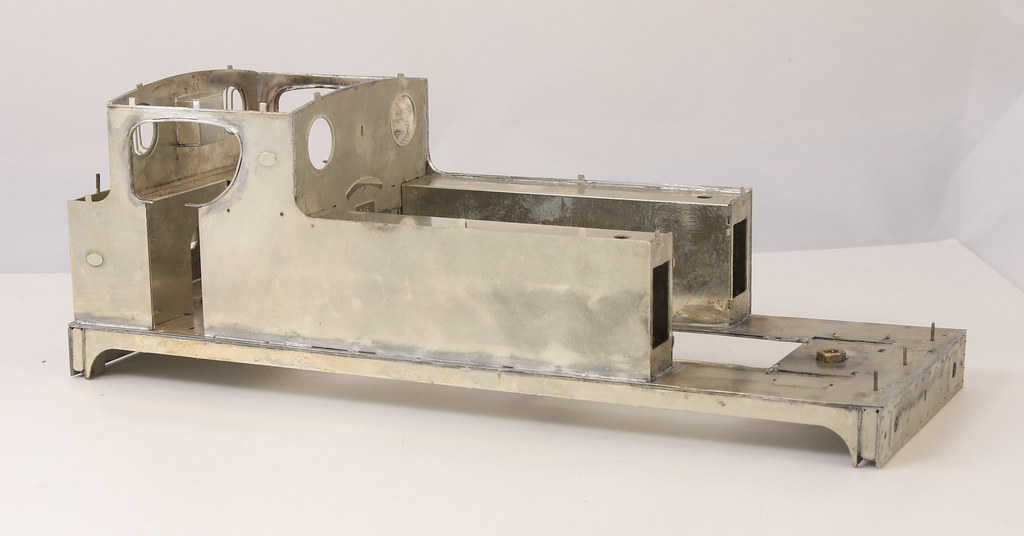

When I saw the casting I recalled that lurking in a spares box was a piece of brass that I had cut to shape for a round top backhead prior to getting more information and making a second more accurate backhead for a 4mm scale loco around 12 or so years ago. I dug it out and to my delight it only needed a minor amount of filing and a few mm cut off the bottom, to be the right size/shape to replace the resin casting. What it did lack was depth, but that was overcome by soldering a curved strip of etch offcut to the back of it.

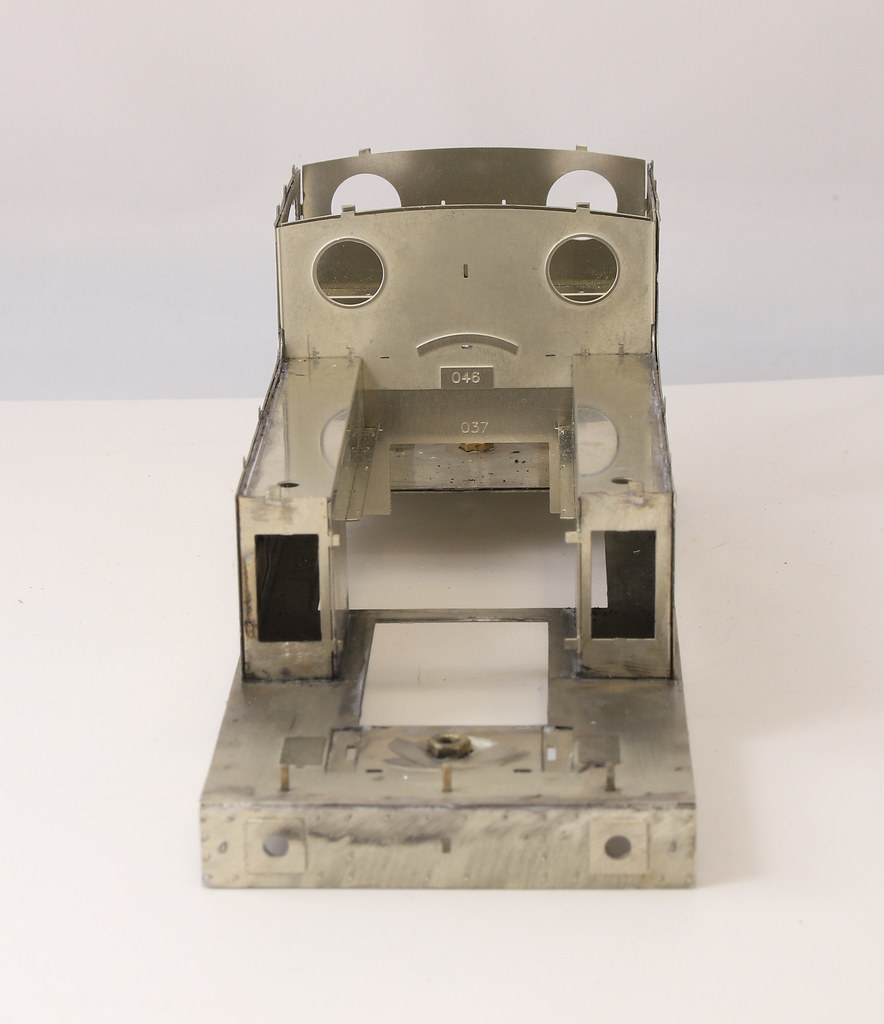

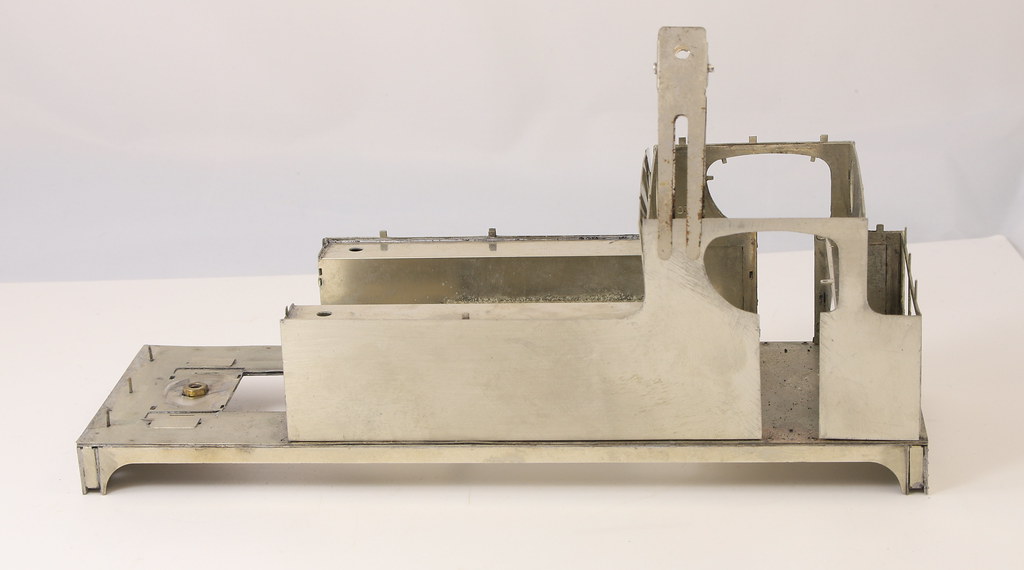

This is the original casting which aside from anything else is slightly lopsided.

This is what I came up with as a replacement which should pass muster in an enclosed cab.

Finally a side by side shot for comparison.