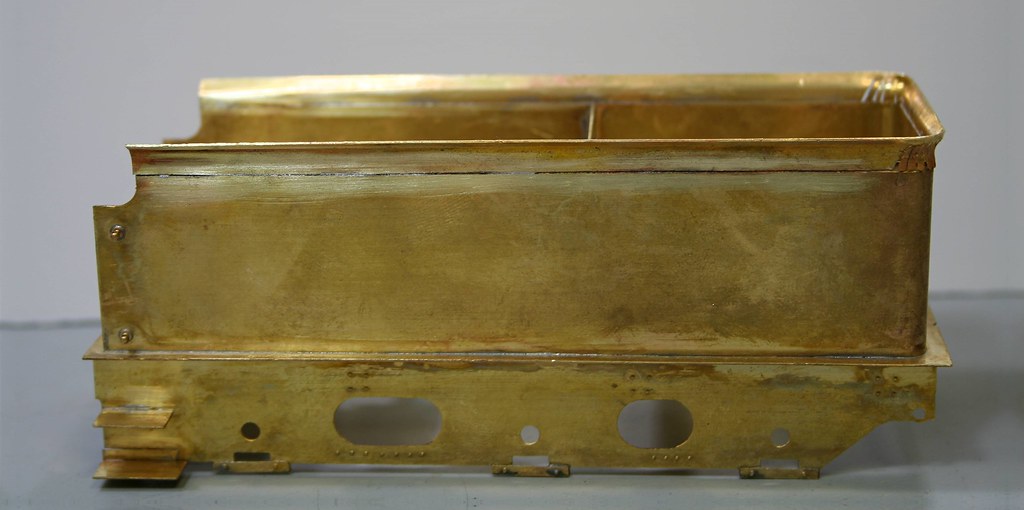

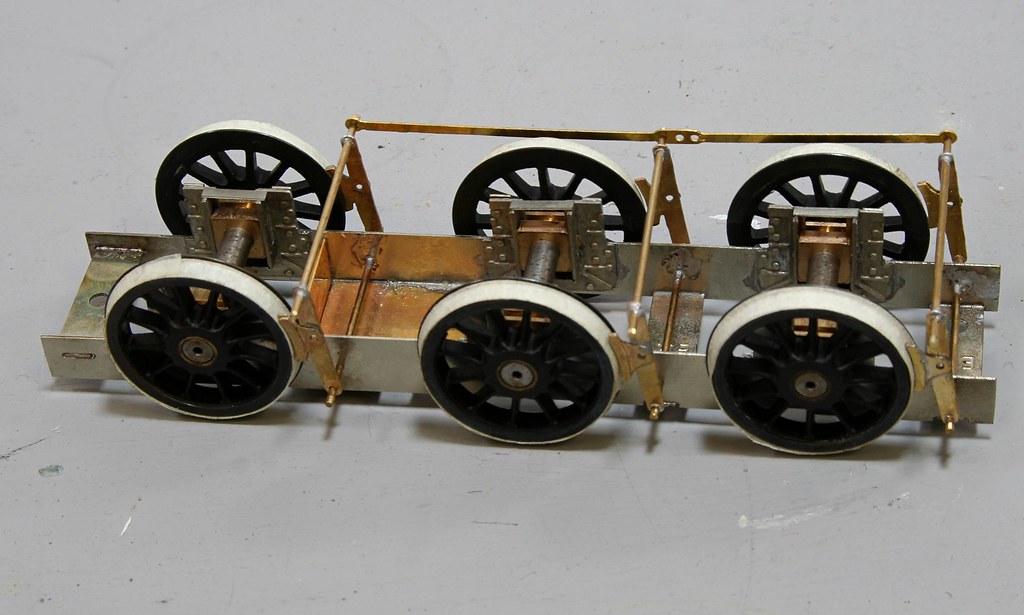

Further progress on the tender for the J6. Starting off with a slight backward step.

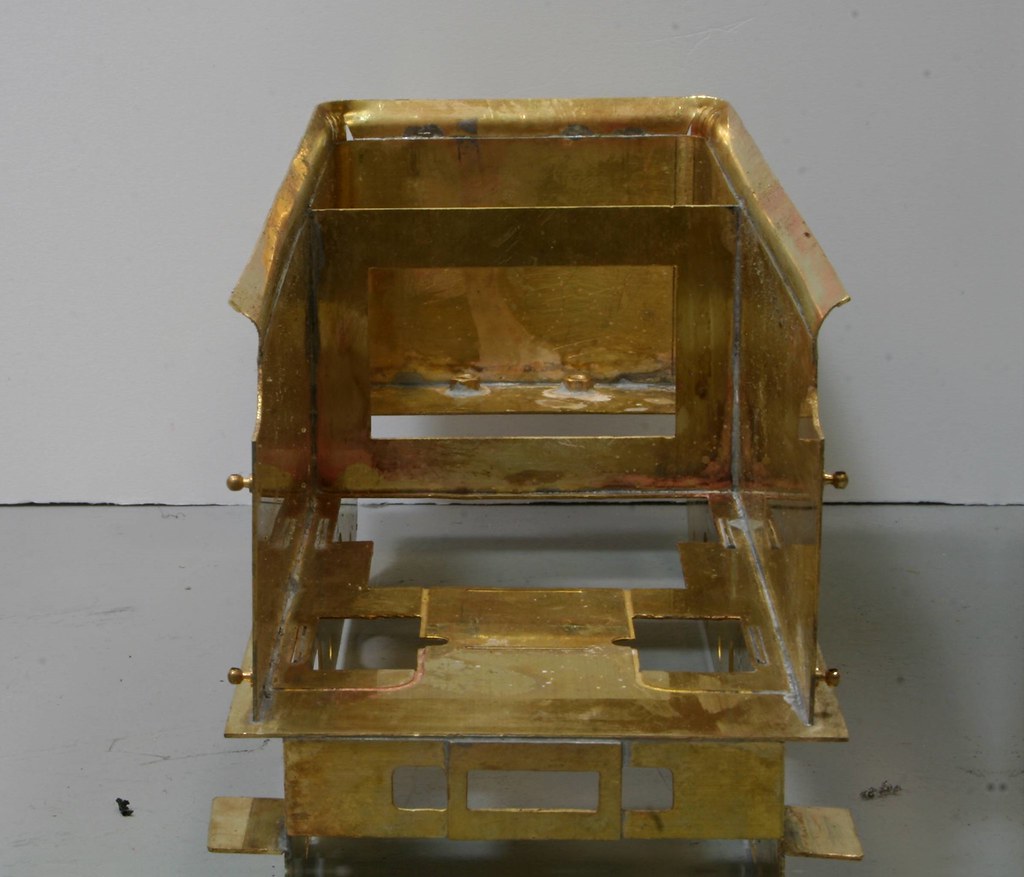

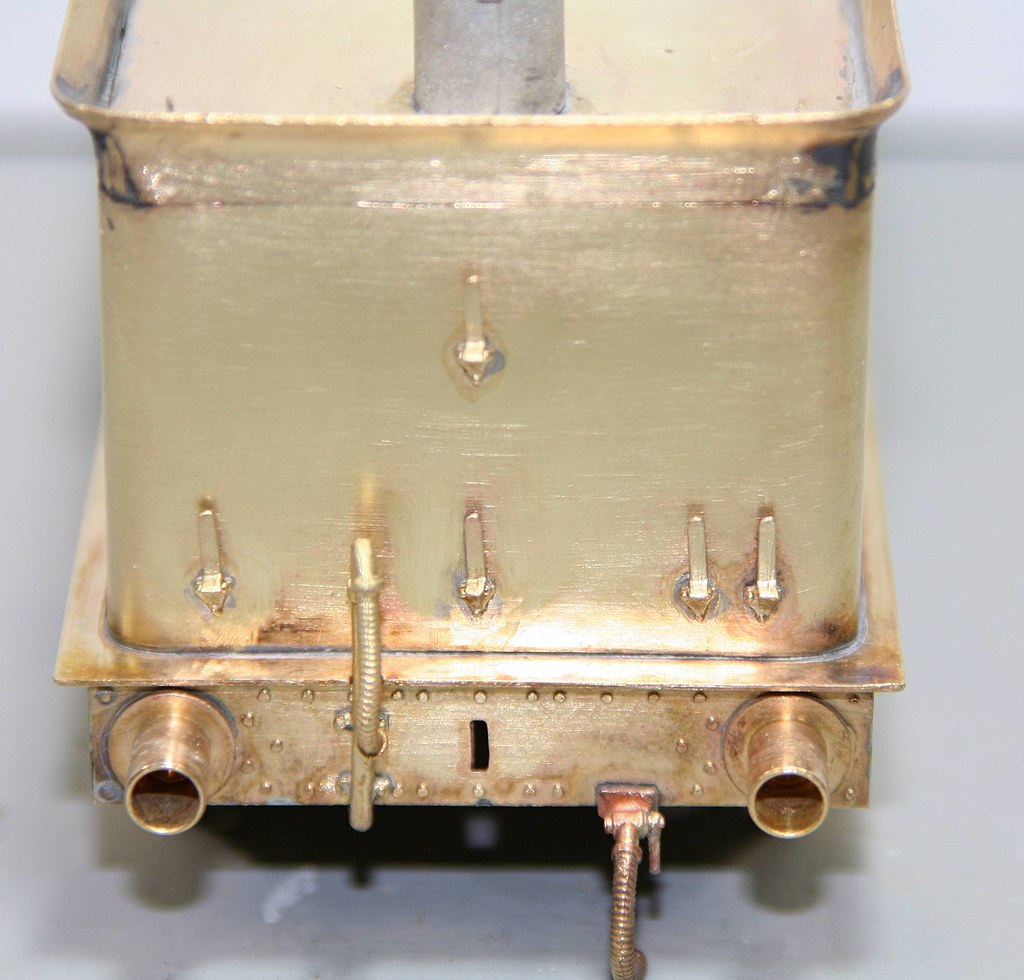

While struggling with the instructions I hadn't read the text when fitting the lifting eyes I just followed the drawing which unfortunately showed the wrong type of backing plate. Reading through the text late last week I saw my error and by coincidence David Hill of Gladiator pointed it out the day after on the Guild forum.

My customer had seen the post and said it didn't matter if they didn't show too much but it was only a few minutes of a job with the microflame and a scalpel to take them off and swap them for the right ones.

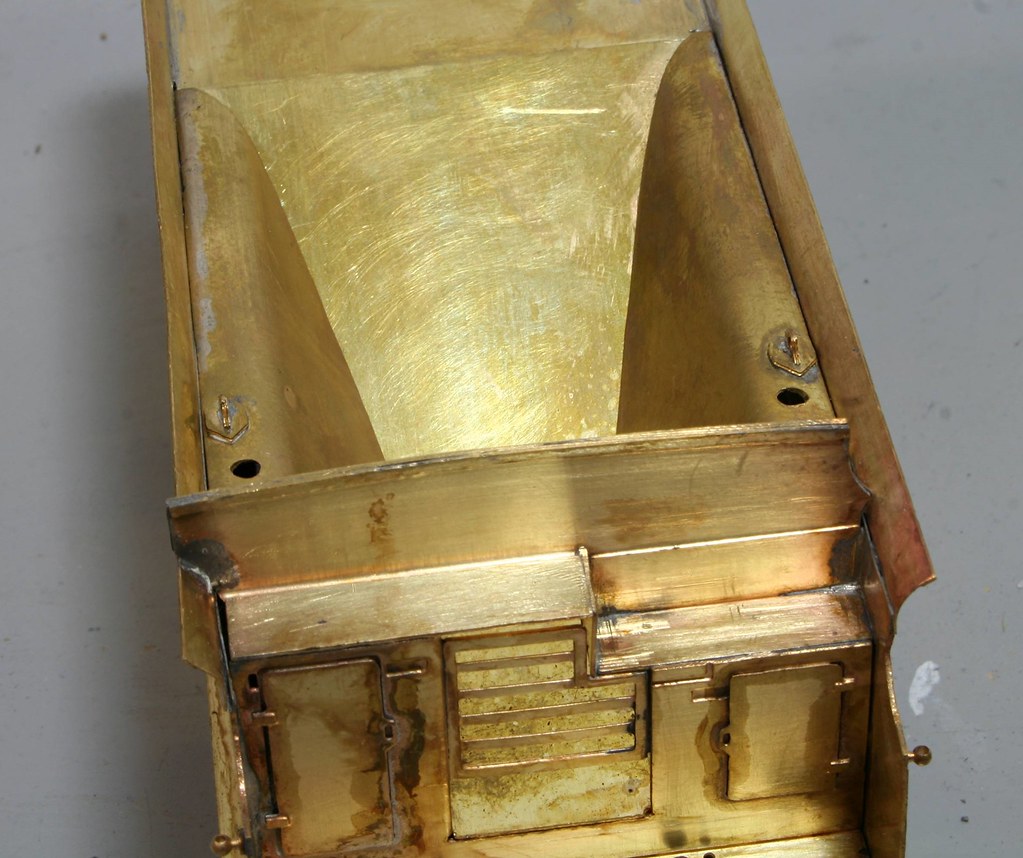

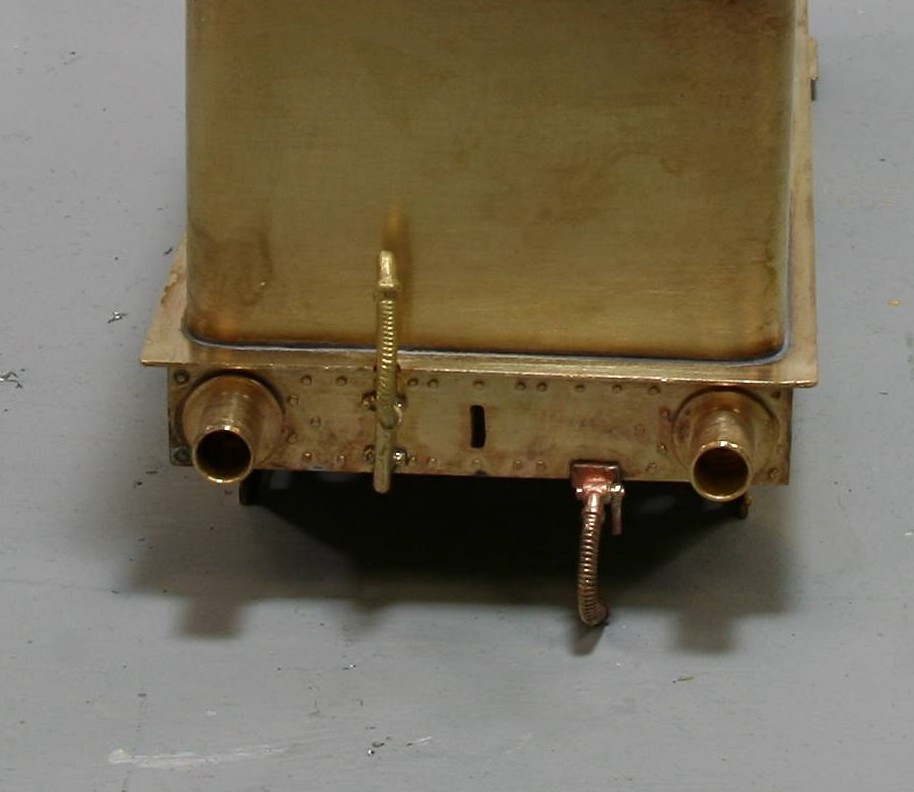

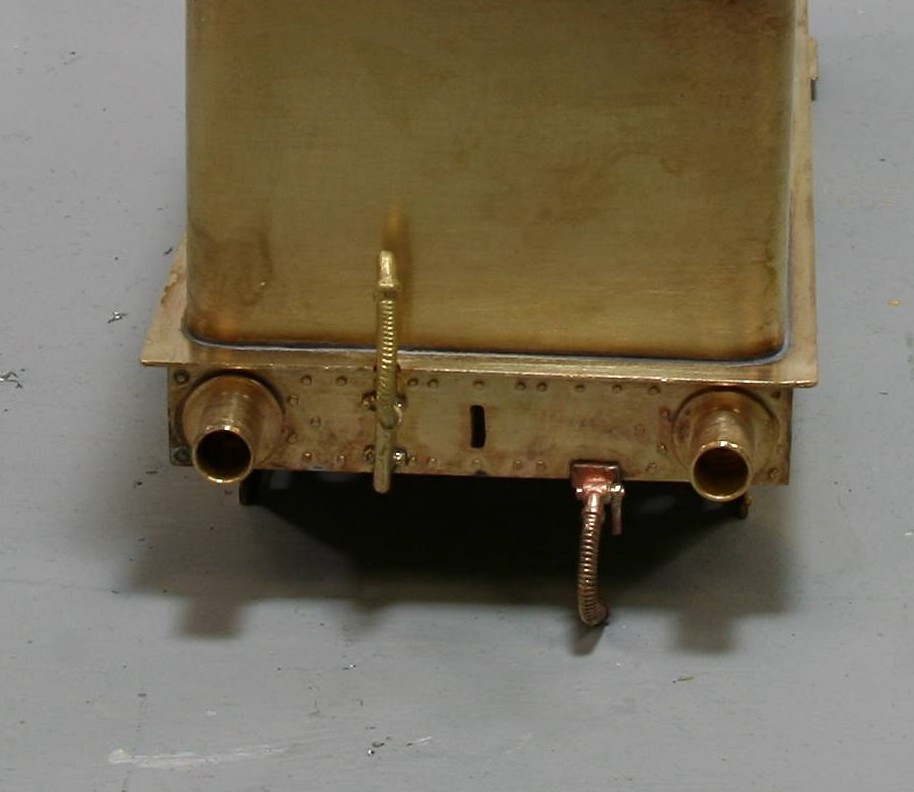

Next I added the vacuum and steam heat pipes to the rear of the tender.

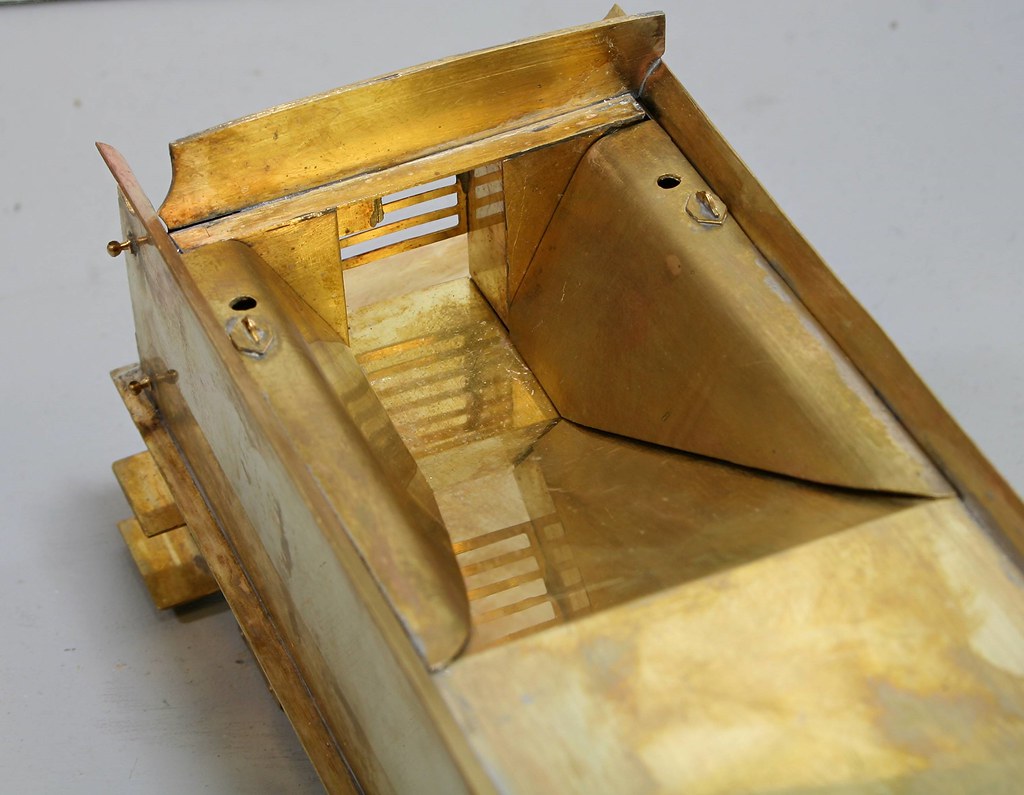

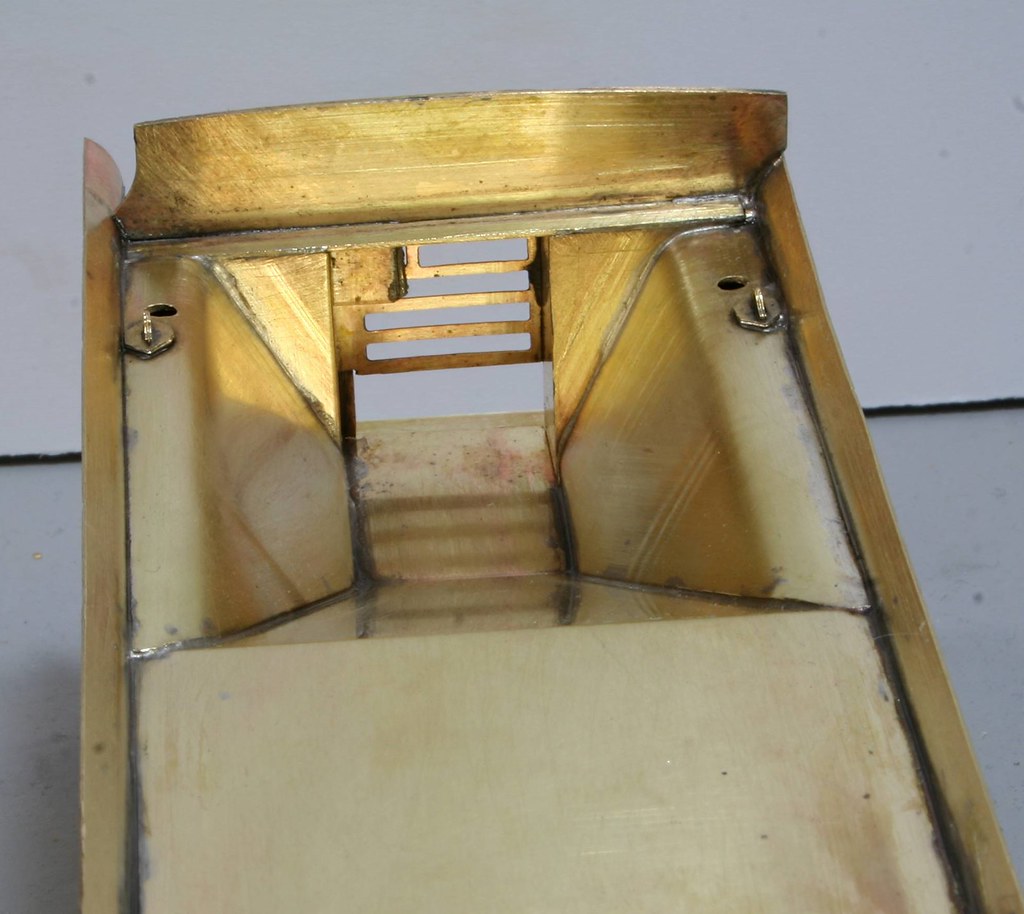

Then I started on the front.

The brake standard was one that I had in my spares box that was left over from the B16 build. The other levers are bent wire and scrap etch.

The bucket is one of Jim McGeown's castings that I had sat on my desk for a long time after I had made a bit of a mess of trying to hollow it out.

I took it back into the workshop to see if I could do anything with it after being informed that the hole in the left hand side was for a bucket. I then remembered the collets that I had made for drilling the valve guide castings on the Streamlined Duchess and used one of them to tidy up the inside of the bucket top using a dental burr and lastly soldered a handle on from scrap etch.