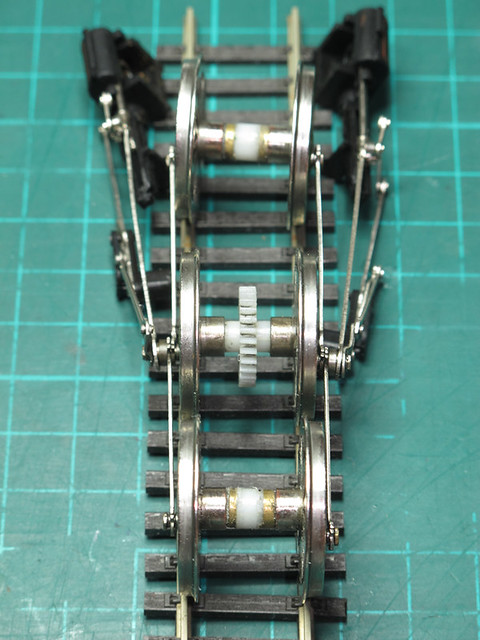

Bachmann split-chassis axle repair method

Posted: Tue Nov 09, 2010 8:30 pm

As requested by Mick B! I know that some of this might sound crude, fiddly, or downright unfeasible to some, but I can assure you all that I've tried this several times with successful lasting results:

When the ends of the plastic middle of the axle (or the "muff" as it is sometimes called) have split, or the whole thing has split in two along its length, and the wheels have gone wobbly and possibly lost their quartering....

1. Drop the chassis-bottom keeper plate (or do whatever else is required) to release the wheelsets.

2. Find, identify, degrease, and match up (i.e fit together dry) the pieces of the axle(s), WITHOUT fitting the wheels into the square sockets in the axle ends.

3. With great care to exactly align any broken bits of axle, use tiny spots of superglue to intially/temporarily hold the axle(s) in one piece. Don't try to simply refit the wheels permanently at this stage in the hope that this much will "do", as the axle will probably quickly split again.

4. If the axles have narrower ends and fat middles, find the size of (say) K & S brass tubing that JUST fits over the narrow ends of the axle and is no fatter externally than the bosses (or stub axles) on the backs of the wheels, and carefully saw off some narrow rings (say 1mm wide at most) from the brass tube, de-burring the cuts thoroughly. 7/32" brass tubing rings a bell in my memory, but you'll have to check as not all Bachmann (or Bachmann style) set-ups appear to be the same, older ones especially may have slimmer axles and bosses.

IF your axles are the same diameter over ther whole length, then the brass tube chosen needs to just fit over the axle but again should be no fatter than the wheel bosses.

5. If your axles have the fat middle bit, then see if the fatter part of the axle is so wide that the wheel bosses have to push tight up against it in order to set the wheels to gauge. Often it is narrower, and with the wheels pushed on to gauge there is still up to a millimetre of the slim part of the axle exposed - if so, you can now jump ahead to step 7. If your wheels push on tight up to the fat middle part of the axle, or almost so, you will have to deal with step 6, below

When the ends of the plastic middle of the axle (or the "muff" as it is sometimes called) have split, or the whole thing has split in two along its length, and the wheels have gone wobbly and possibly lost their quartering....

1. Drop the chassis-bottom keeper plate (or do whatever else is required) to release the wheelsets.

2. Find, identify, degrease, and match up (i.e fit together dry) the pieces of the axle(s), WITHOUT fitting the wheels into the square sockets in the axle ends.

3. With great care to exactly align any broken bits of axle, use tiny spots of superglue to intially/temporarily hold the axle(s) in one piece. Don't try to simply refit the wheels permanently at this stage in the hope that this much will "do", as the axle will probably quickly split again.

4. If the axles have narrower ends and fat middles, find the size of (say) K & S brass tubing that JUST fits over the narrow ends of the axle and is no fatter externally than the bosses (or stub axles) on the backs of the wheels, and carefully saw off some narrow rings (say 1mm wide at most) from the brass tube, de-burring the cuts thoroughly. 7/32" brass tubing rings a bell in my memory, but you'll have to check as not all Bachmann (or Bachmann style) set-ups appear to be the same, older ones especially may have slimmer axles and bosses.

IF your axles are the same diameter over ther whole length, then the brass tube chosen needs to just fit over the axle but again should be no fatter than the wheel bosses.

5. If your axles have the fat middle bit, then see if the fatter part of the axle is so wide that the wheel bosses have to push tight up against it in order to set the wheels to gauge. Often it is narrower, and with the wheels pushed on to gauge there is still up to a millimetre of the slim part of the axle exposed - if so, you can now jump ahead to step 7. If your wheels push on tight up to the fat middle part of the axle, or almost so, you will have to deal with step 6, below