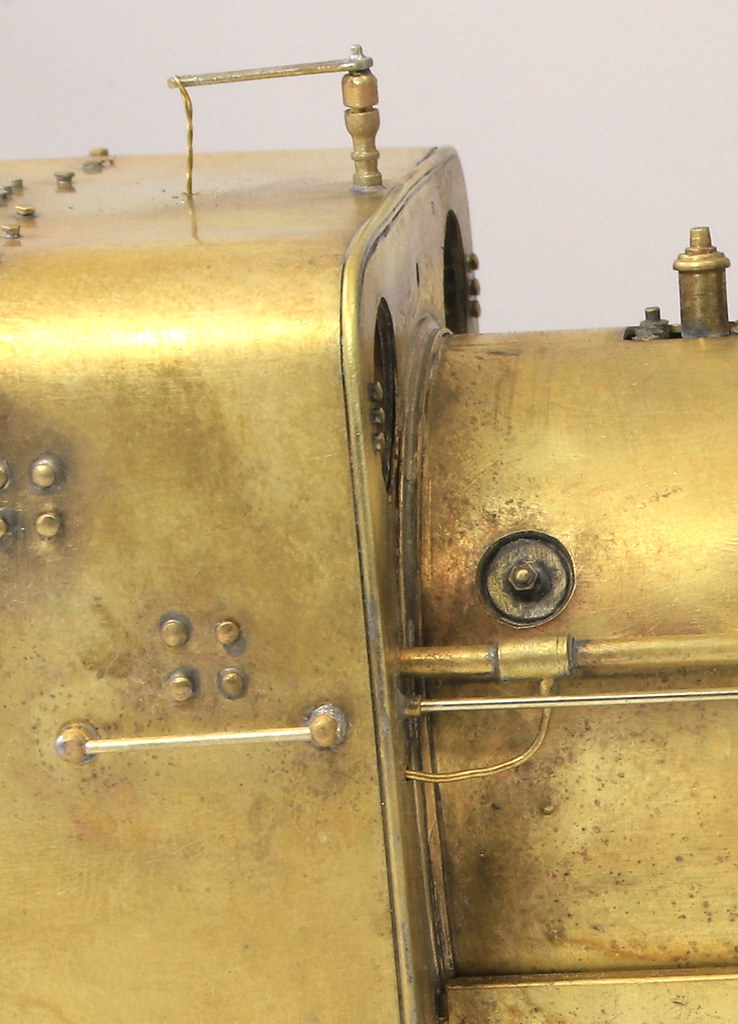

The left side handrail caused a few problems because the etched hole in the cab front, to which I had soldered the tube for the handrail proved to be slightly out of position. I am not sure whether it was a vagary of the hand drawn art work which I have then exacerbated as I have opened the hole with a broach or that my positioning of the boiler was slightly low.

To make it all line up I had to remove the stub of tube, fill the hole with brass rod and file flush then redrilling the hole slightly lower.

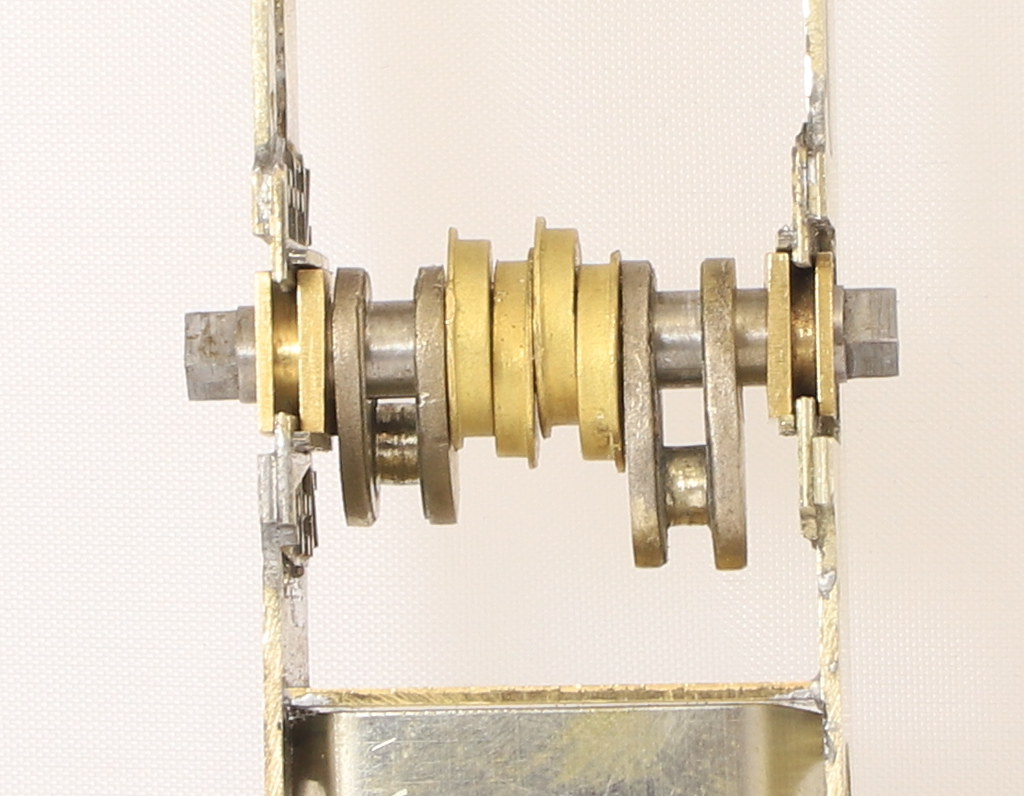

I also drilled the rims of the buffer stocks and inserted some scale hardware fittings the collar of the buffer stocks is quite small so it was a bit nerve wracking drilling with a 0.4mm drill bit, but it came out okay.

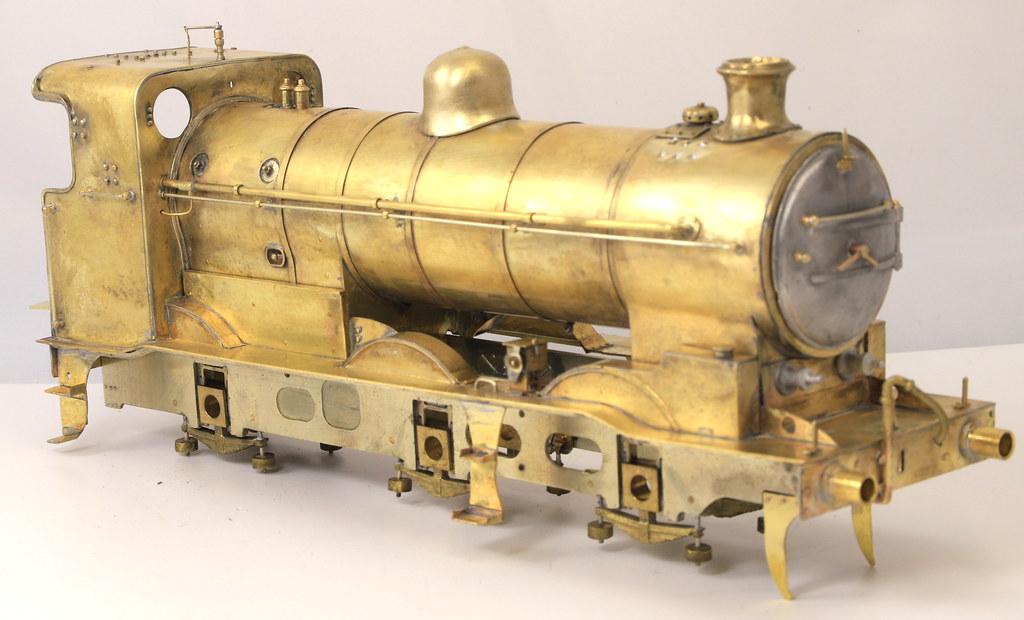

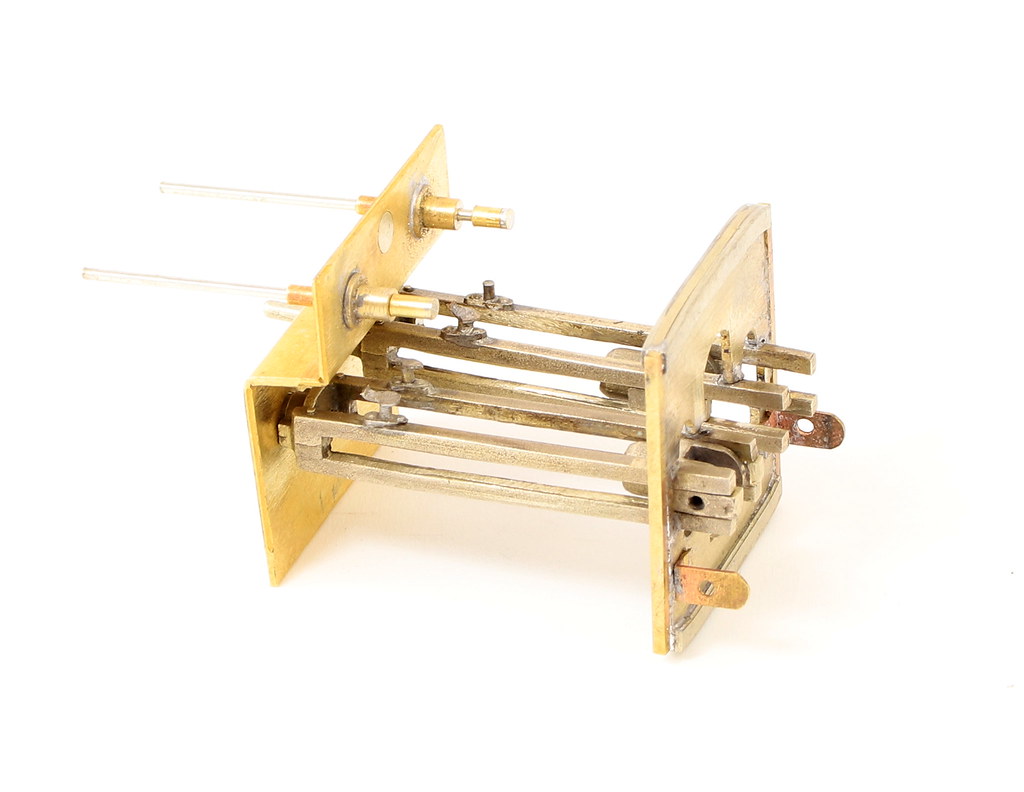

All the boiler fittings are soldered in place with the exception of the smokebox door which it just resting in place for the photos.

The front steps come with an interesting fold up support which makes them fairly rigid but before I had finished fitting the front one’s, I had managed to bend the rear ones so I soldered some 2x1mm bar behind them to give some strength.

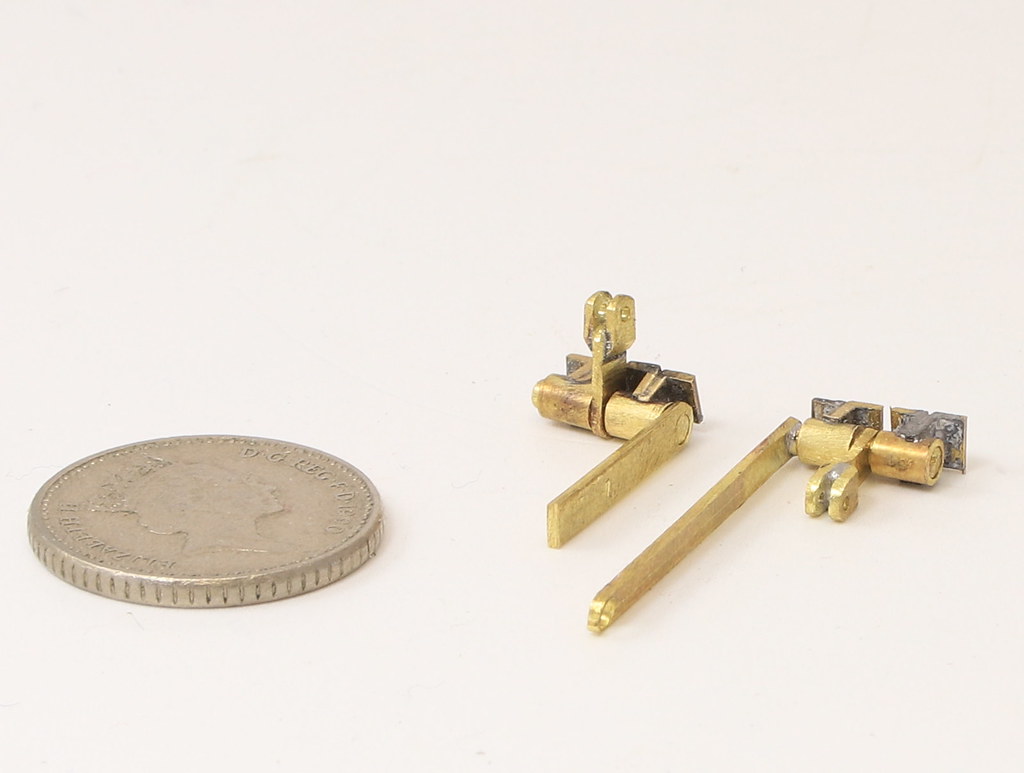

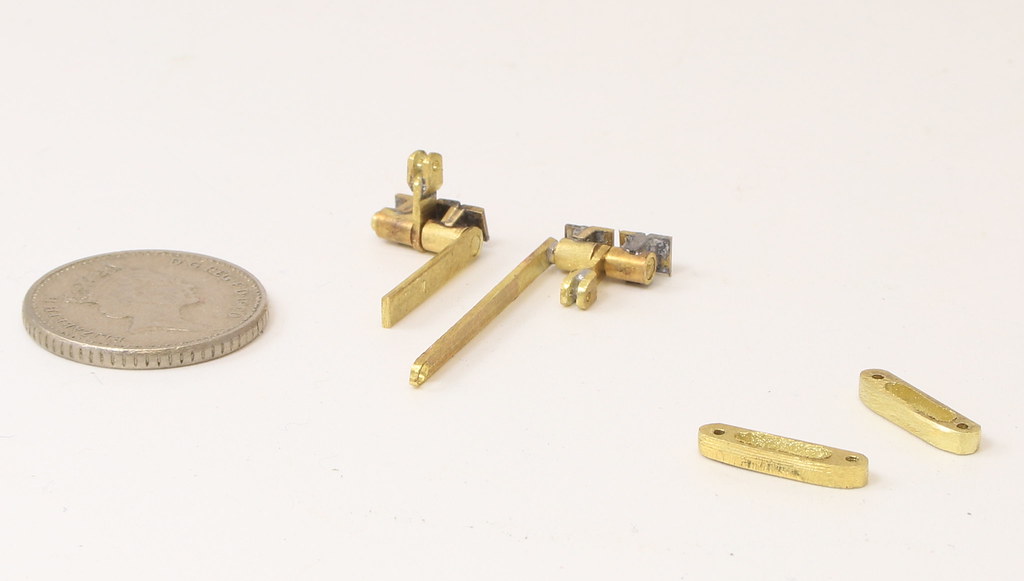

The only things left to fit, are a pair of globe lubricators that sit on the front of the sandboxes either side of the smokebox. The reason that I haven’t fitted them yet is that I have lost them. I bought them at the same time as the backhead and some additional valve rods so I know that they are here somewhere but can I find them….

Of course, the moment I order some more to replace them they will pop out from where they are hiding so I am holding off for the minute.